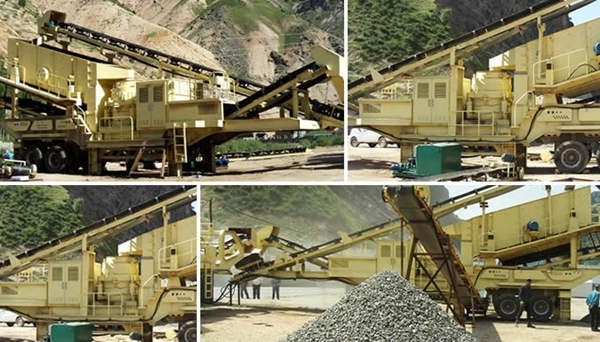

Rubber tire mobile crusher

Production capacity: 150 t/h

Processing material: construction garbage

Application: ore crushing, construction waste recycling, building aggregate production, etc

The Application and Description of Rubber Tyred Mobile Crusher:

Rubber tyred mobile crusher is mainly used in metallurgy, chemical industry, building materials, water and electricity industries for processing materials need to be moved, especially used for stone crushing in highways, railways, hydroelectric projects and other liquidity operations. Therefore, the user can use a variety of configurations according to the type of raw materials, sizes and finished materiel requirements.

The Performance Characteristics of Rubber Tyred Mobile Crusher:

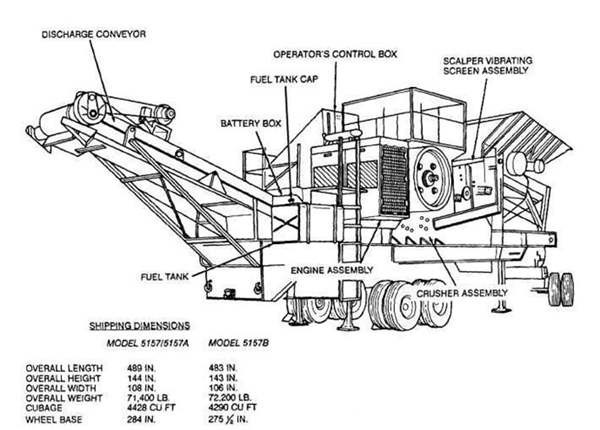

1. Strong movability: Rubber tyred mobile crusher has shorter length, various crushers are installed on separate removable chassis, with short wheelbase and small turning radius, so it can run flexibly on the ordinary roads in operation areas.

2. Reducing material transportation cost: Rubber tyred mobile crusher can process materials on-site without moving materials away from the scene, which greatly reduces the shipping cost.

3. Flexible combination and strong adaptability: Rubber tyred mobile crusher can do both "screening after crushing" and "crushing after screening" according to different breaking technological requirements, and it can do two-stage crushing and screening system of rough crushing and fine crushing, or three-stage crushing and screening system of rough crushing, middle crushing and fine crushing according to actual demand, and it also can run independently, with big flexibility.

Technical data

| Model | HX938HD80 | HX1149HD98 | HX1349HD110 | HX1349HD125 |

| Trasportation Length(mm) | 12600 | 13500 | 14500 | 15200 |

| Trasportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Trasportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Length(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial | Triaxial |

| Jaw Crusher | HD80 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge Opening Size(mm) | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibtrating Feeder | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Converyor | B800×8.5M | B1000×9.5M | B1000×11M | B1200×11M |

| Side-Opening Belt Converyor(Optional) | B500×3M | B650×3.5M | B650×4M | B650×4M |

| Genset(Optional)(kw) | 200 | 250 | 270 | 400 |

| Iron Separator(Optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

HOT PRODUCT

-

-

Jaw Crusher

The Jaw crusher is used for Primary crushers and Secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 mpa. There are two types of Jaw crusher:coarse jaw crusher and fine jaw crusher.

-

-

Impact Crusher

Impact crusher is suitable for materials whose compressive strength is under 350Mpa, and particle size is less than 500mm. With end products in cubic shape, the impact crusher is widely used for sand and rock producing in the industry of roads, railways, reservoir, electricity power and building materials and so on.